An Overview of EMCCD Sensor Enhancements

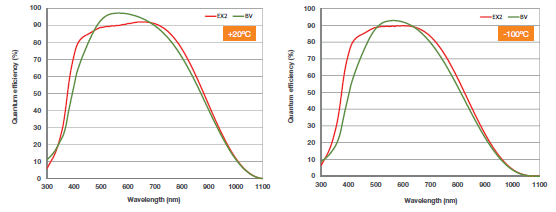

Figure 1: Back-illuminated EMCCD sensor QE curves, comparing standard ‘BV’ mid-band AR coating versus new EX2 dual AR coating.

Reference data available at +20°C and -100°C sensor cooling temperatures.

EX2 Technology - Extended QE with Dual AR coating

Available on the new speed-boosted iXon Ultra 897 and 888 cameras, EX2 technology facilitates broadening of the QE range of the back-illuminated sensors through implementation of a new dual layer anti-reflection coating process, developed by sensor manufacturer e2v (Chelmsford, England). The net effect is to offer significantly improved sensitivity in both the blue and NIR wavelength regions, whilst maintaining ~ 90% QE across the remainder of the visible region.

QE varies somewhat as a function of sensor cooling temperature, so it can be useful to view reference QE curves at two extreme temperatures to achieve a sense of this dependence. Figure 1 shows QE curves for the new EX2 dual AR coated sensors versus that of the 'standard' BV single AR coating (mid-band optimised) at both +20°C and -100°C sensor cooling temperatures. It is clear, notably under more typical conditions of deep cooling, that the EX2 curve exhibits a marked widening of the QE response into both the blue and red/NIR wavelength ranges, while maintaining ~ 90% QE in the important region in between.

Для продолжения чтения вы можете скачать полную версию материала по ссылке ниже